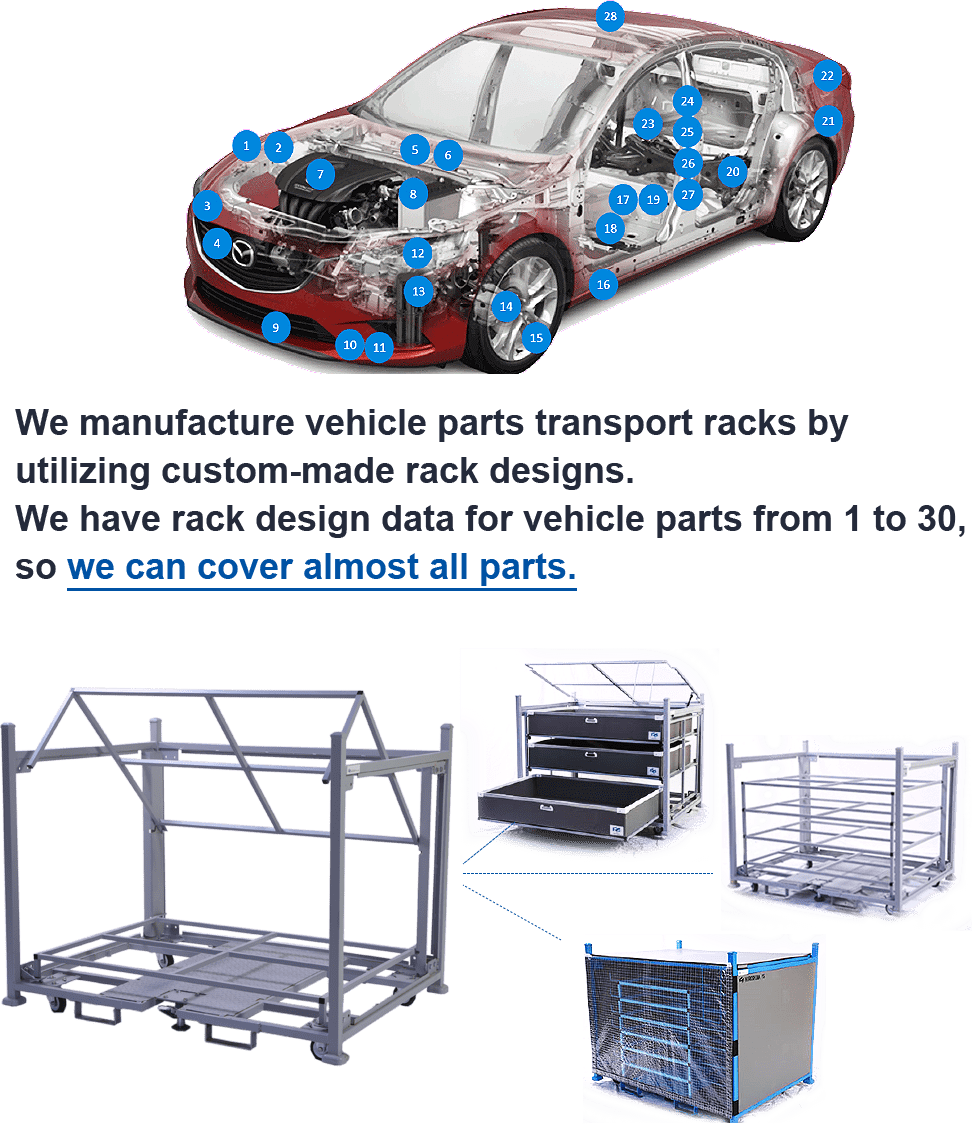

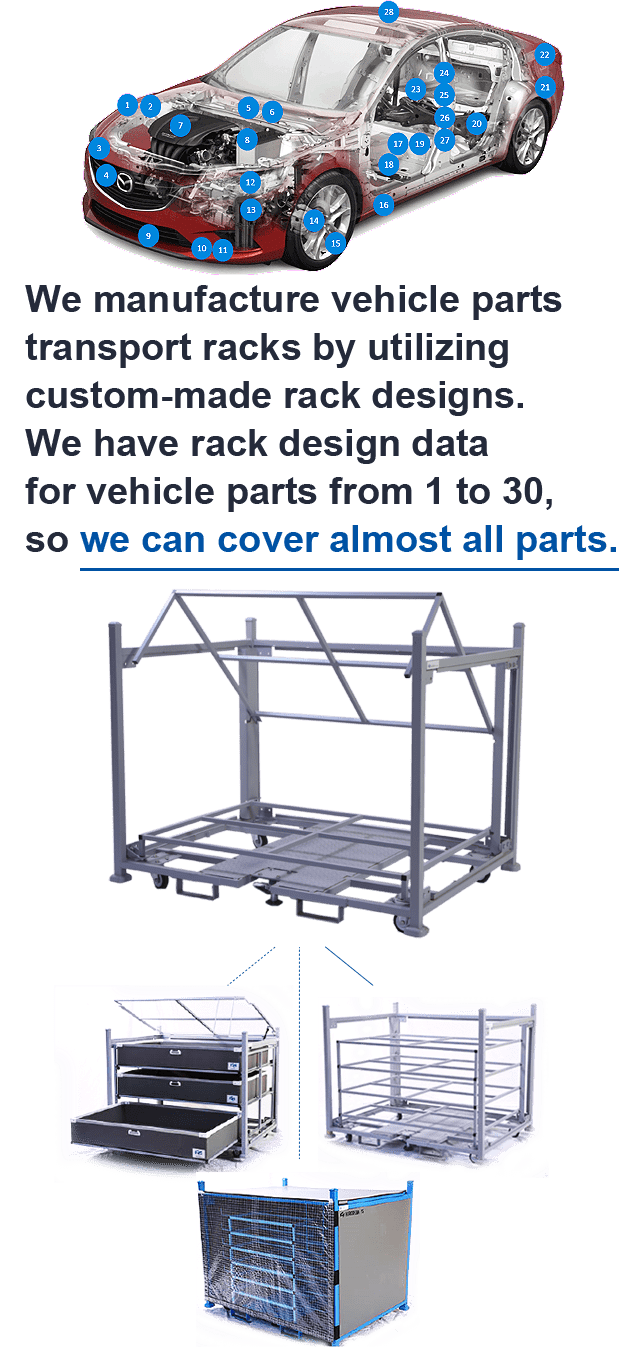

Hiroshima P.S. has achieved high cost performance

by combining the racks design and production capabilities it has developed over many years,

and by working on design from theory as well as ease of transport.

In the automation of conveyor sites,

the smooth cooperation between production, development and sales departments,

and the participation of engineers in sales,

enable us to propose many benefits to our customers, and they are very satisfied with our proposals.

Utilizing the technical capabilities cultivated through rack design experience, we are able to provide total production by combining transport racks and AGV equipment development.

Over 3,000 units are manufactured annually.

We accept orders for custom-made racks and also offer a rental service, providing you with as much as you need, when you need it.

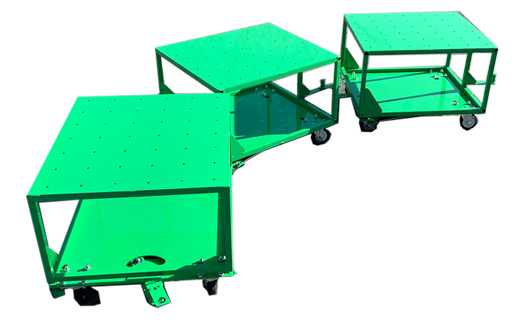

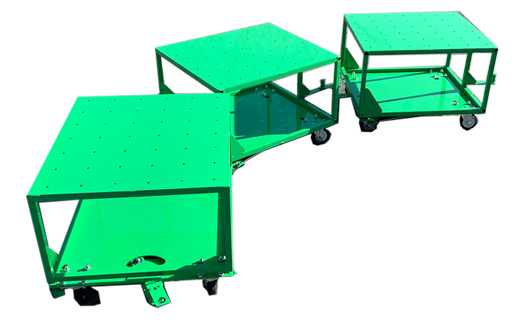

Achievements in automotive parts produced on transport trolleys.

*Prices vary depending on specifications, so we will provide you with a quote upon inquiry.

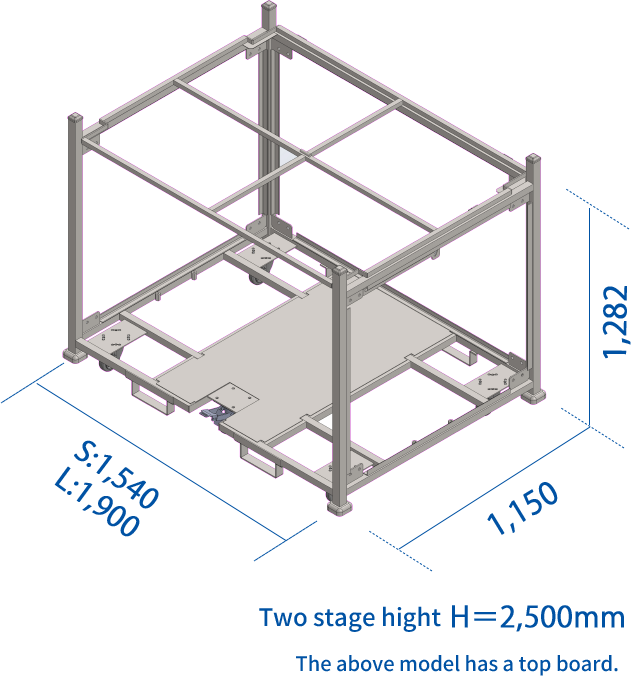

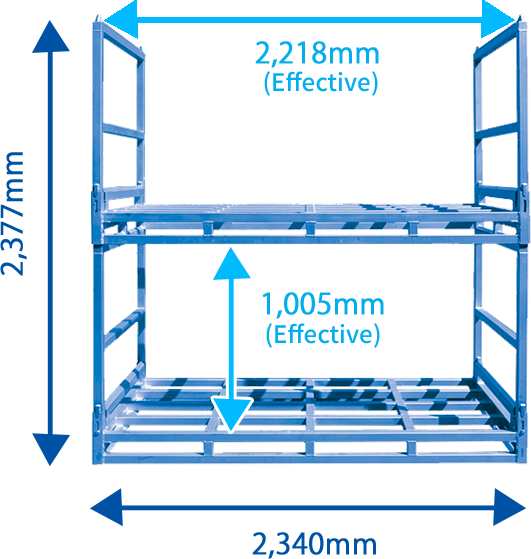

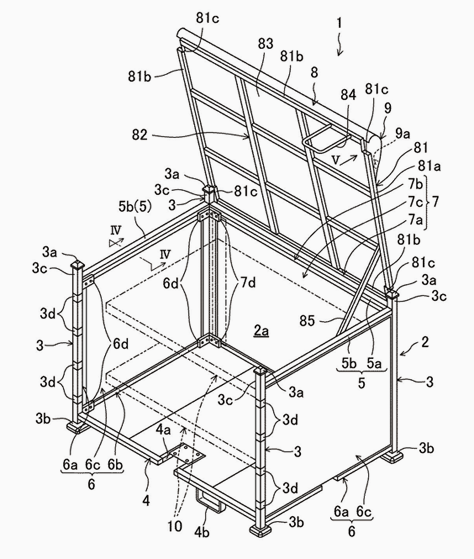

L-packet system racks are space utilization system racks with a maximum load capacity of 1 ton designed to cut costs in logistics.

It is also designed with a pallet function,

so it can be transported directly from a truck with a lift,

eliminating the need for pallets and reducing

unnecessary expenses such as disposal costs.

It is highly appreciated by people in the logistics

and warehouse management industries.

Semi-modular trolleys and L-Package system racks are also available for rental services.

| Width (mm) |

Depth (mm) |

Height (mm) |

Rental charge | Guarantee charge | ||

| S | Effective | 1,420 | 1,030 | 934 | 1,050yen~(tax exclueded) | 100yen~ |

| Outside | 1,540 | 1,150 | 1,197 | |||

| Number mounted on 10t truck*1: 24 dolly | ||||||

| L | Effective | 1,780 | 1,030 | 934 | 1,250yen~ | 100yen~ |

| Outside | 1,900 | 1,150 | 1,197 | |||

| Number mounted on 10t truck*1: 24 dolly | ||||||

*1 10t truck: Depth 9,600mm

Rental charge : A management fee is required in addition to the compensation fee. A separate charge of 300 yen/unit will be applied.

Rental fees vary depending on the number of units contracted for the first time.

Compensation fee : It can be used for options and trolley repairs

| ORIGINAL | Width (mm) |

Depth (mm) |

Height (mm) |

Price | Rental charge |

| Effective | 2,218 | 1,141 | 1,068.5 | 199,000yen(tax exclueded) | 3,000yen~(tax exclueded) |

| Outside | 2,340 | 1,159 | 2,340 |

| LIGHT | Width (mm) |

Depth (mm) |

Height (mm) |

Price | Rental charge |

| Effective | 2,241 | 1,141 | 1,070.5 | 99,000yen(tax exclueded) | 1,500yen~(tax exclueded) |

| Outside | 2,350 | 1,150 | 1,259.5 |

This is a transport vehicle that excels in large-volume transport, turning performance, tracking performance, and quietness.

With the “triple attack” of “safety”, “space saving” and “reducing logistics costs” directly reduces on-site costs!

| Name | 4WS/standard type | 4WS/small type | 4WS/handcart switching type |

| Appearance |  |

|

|

| Size of the pallet for conveyance | L1,400×W1,050(mm) | L600×W600(mm) | L1,395×W1,100(mm) |

| Maximum loading capacity | 350kg/500kg(*Option) | 100kg | 500kg |

| Minimum turning radius | 2.0m | 1.2m | 2.1m |

| Outside dimension | L2,081×W2,050×H315 | L1,050×W600×H500 | L2,300×W1,100×H324 |

| Feature |

|

|

|

| Price | 198,000yen | 128,000yen | Contact us |

| Name | |

| Appearance |  |

| Size of the pallet for conveyance | L1,395×W1,100(mm) |

| Maximum loading capacity | 500kg |

| Minimum turning radius | 2.1m |

| Outside dimension | L2,300×W1,100×H324 |

| Feature |

|

| Price | Contact us |

| Name | 4WS/small type |

| Appearance |  |

| Size of the pallet for conveyance | L600×W600(mm) |

| Maximum loading capacity | 100kg |

| Minimum turning radius | 1.2m |

| Outside dimension | L1,050×W600×H500(mm) |

| Feature |

|

| Price | 128,000yen |

| Name | 4WS/standard type |

| Appearance |  |

| Size of the pallet for conveyance | L1,400×W1,050(mm) |

| Maximum loading capacity | 350kg/500kg(*Option) |

| Minimum turning radius | 2.0m |

| Outside dimension | L2,081×W2,050×H315(mm) |

| Feature |

|

| Price | 198,000yen |

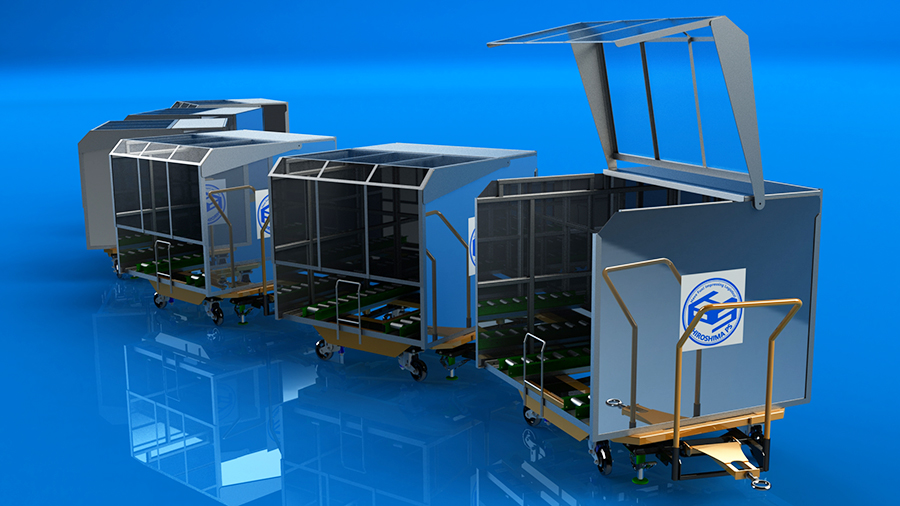

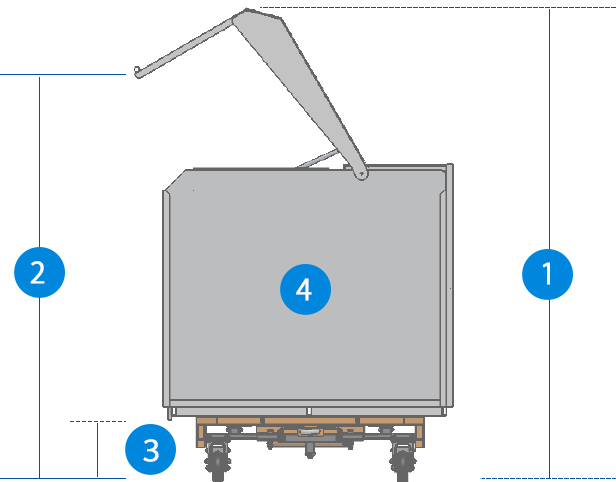

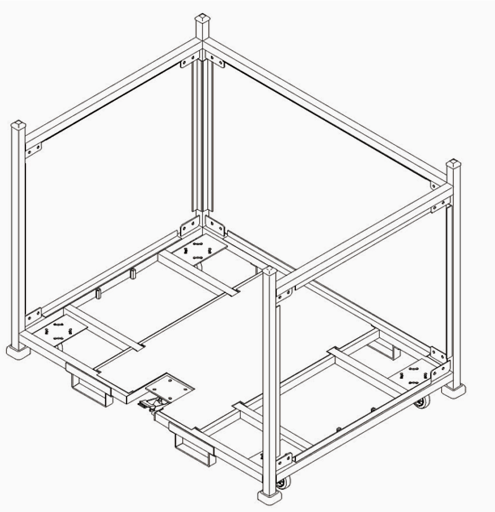

This is a new type that is easy to use on site and can be used in rainy weather.

Even in places without roofs, such as between buildings, cargo will not get wet from the rain. Bulk items such as products and materials before packaging can be loaded as is.

| Name | 4WS/type BULK |

| Size(mm) | L2,222×W1,375×H1476 |

| Overall height when open(mm)1 | 2,196 |

| Maximum height of handle(mm)2 | 1,903 |

| Product mounting height(mm)3 | 398 |

| Mountable inside dimensions(mm)4 | W1,219×D1,264×H1,025 |

| Maximum loading capacity | 300kg/unit(recommended) |

| Towing speed | under 4km/h(recommended) |

| Minimum turning radius | 2.0m |

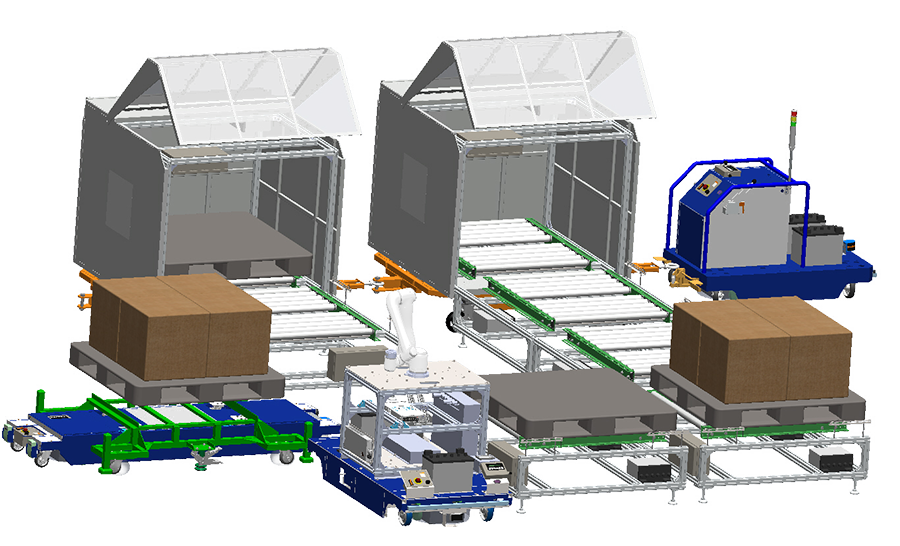

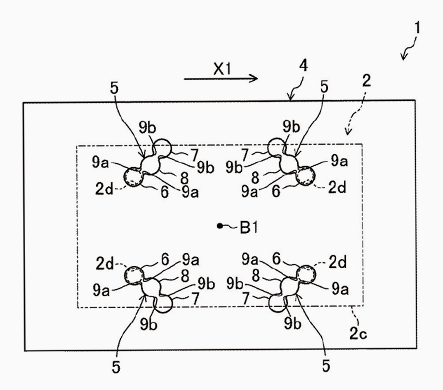

Smart on-site logistics is the name of the factory automation (FA) proposed by Hiroshima PS.

We propose automation inside and outside the factory premises by combining transport racks, which we have cultivated over many years of know-how, with AGVs that stands for “Automated Guided Vehicle”.

Since we have developed many types of AGVs, we are able to implement automation tailored to the customer’s needs, even from partial implementation.

It is also possible to design a combination of transport and transfer as a set, so please feel free to contact us for more information.

A combination of unmanned carts and 4WS trolleys allows for mass transportation between factories.

Reference price: 8.4 million yen~

Installation costs are not included, so we will let you know at the time of consultation.

This is an outdoor transport trolley that can be used in rainy weather and has high tracking performance due to the 4WS mechanism.

Reference price: @600,000 yen~ / 4WS trolley included

Minimum order of 4 units.

Combined with unmanned transport systems such as towed AGVs, cart AGVs and 4WS trolleys, the receiving and dispatching of goods between locations can be automated.

Reference price: 1.3 million yen~

Automate transportation between indoor locations. Combinations such as small 4WS trolleys enable transport in narrow aisles.

Reference price: 1.6 million yen~

includes 3 regular small 4WS trolleys

Small 4WS trolleys can be customized for appropriation.

Equipment costs for magnetic tape will be charged separately.

We can also sell magnetic tapes and other equipment only.

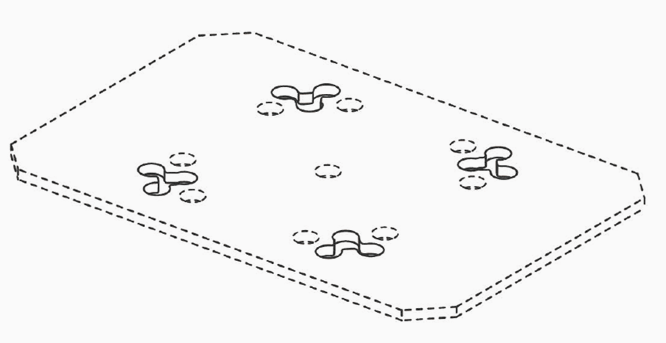

It can get under the dedicated conveyance and lift it for direct transport to any defined location.

Reference price: 4.2 million yen~

By combining an on-board AGV and a collaborative robot, it is possible to wait at any predetermined location and transfer by a team.

Reference price: 7.6 million yen~(Include system construction fee)

As a package product for small and medium-sized companies, we offer a high cost- performance product that includes a towable AGV and a 4WS cart. It is a start-up kit, so to speak, with equipment settings focused on safety equipment and essential functions, and with the installation of guides and simple settings, logistics can be improved from the day of purchase. In addition, future functionality can be upgraded by taking advantage of expandability.

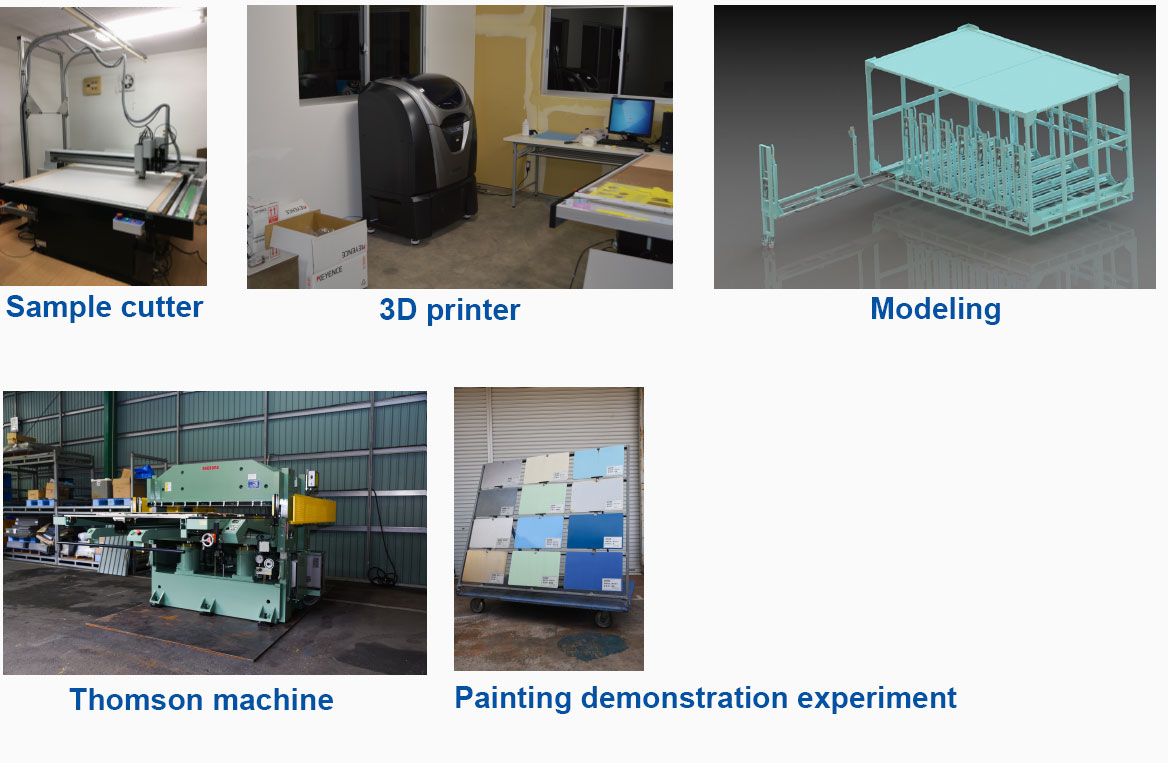

We offer our customers the opportunity to visit our factory on request.

We also provide 3D verification of drawings, trial runs before delivery, reproduction of problems, verification and analysis of test data, so that even those who are worried about automation can introduce it with peace of mind. If you are interested, please feel free to visit us.

| Machinery | Manufacture name | Ability | Number |

| CATIAV5 | Dassault Systèmes | 3D-CAD software | 1 |

| SolidWorksPremium | Dassault Systèmes | 3D-CAD software | 1 |

| SolidWorksProfessional 2022 | Dassault Systèmes | 3D-CAD software | 6 |

| SolidWorks Electrical Professional |

Dassault Systèmes | 3D-CAD software | 1 |

| Automatic welding machineFDB4L-P500L | Daihen | 7-axis robot | 2 |

| Automatic welding machineAX-V6 | Daihen | 6-axis robot | 1 |

| Automatic welding machineAX-V6L | Daihen | 6-axis robot | 1 |

| Plasma cutting machine | Daihen | for Daihen AX-V6 robot | 1 |

| Die cutter –Thomson-OP-1712-120 | Akebono Machine | 1 | |

| Cutting machine systemHT-1613FNE | Laserck | 1 | |

| 3D printerAGIRISTA-3110 | Keyence | 1 | |

| Arm stitcher4.5 | NIKKI | 1 | |

| Panel sawE2500 | Tanaka Machine Industry | 1 |

| Machinery | Manufacture name | Number |

| Semi-automatic welding machine | Daihen | 14 |

| Dust collectorCFK-8 | Showa Denki | 1 |

| Collaborative robotcobot cell E(CB-EC63) | THK | 1 |

| Handling robotM710iC/50 | FANUC | 1 |

| Shearing machineM2545 | Amada | 1 |

| Brake machineM-350 | Amada | 1 |

| Brake machineTP-25X | Amada | 1 |

| Band saw machineHFA250 | Amada | 1 |

| Angle processing machineMW-35 | Nitto-kohki | 1 |

| Rebar bender | 2 | |

| Digital platform scalesSD-300 | SHUZUI SCALES | 1 |

| Dronephantom4 etc. | DJI | 3 |

| Industrial sewing machineLK-1900B-WS | JUKI | 1 |

Hiroshima PS applies for patents for the purpose of protecting its technology and intellectual property.

Please contact us if you wish to obtain a licence for the patent owned by our company.

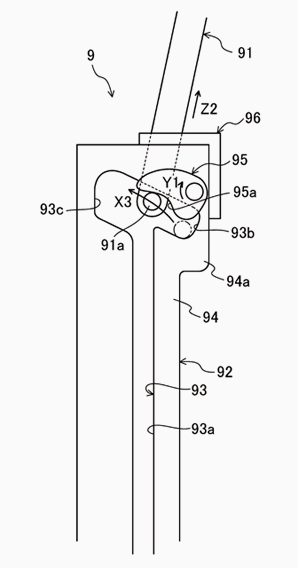

Patent No.670844 Pallet

Patent No.6782966

Mounting bracket for casters

Patent No.6755040

Stay for pallet

Others, Brake units : Special request 2017-074767,

Towing trolley (Special request 2017-074766),we have also Tire rack (Patent No. 6092635)

Design registration 1653938 and other caster mounting hardware

Design registration 1648615 and other transportation pallets

Other products include tire racks design registration 1500533.

Registration 6182257 Module trolley

Registration 6496284 Smart on-site logistics

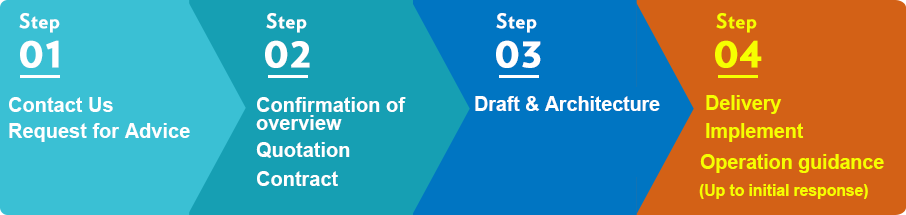

Module trolleys and system racks can be ordered as individual units at any time.

AGV products are available for partial installation in accordance with the customer’s factory layout. Please feel free to contact us.

We will work together to offer maximum benefits at minimum cost.

1650-2 Kuba, Fukutomi-cho, Higashi-Hiroshima city, Hiroshima prefecture

739-2303 Japan

TEL +81-82-430-1003